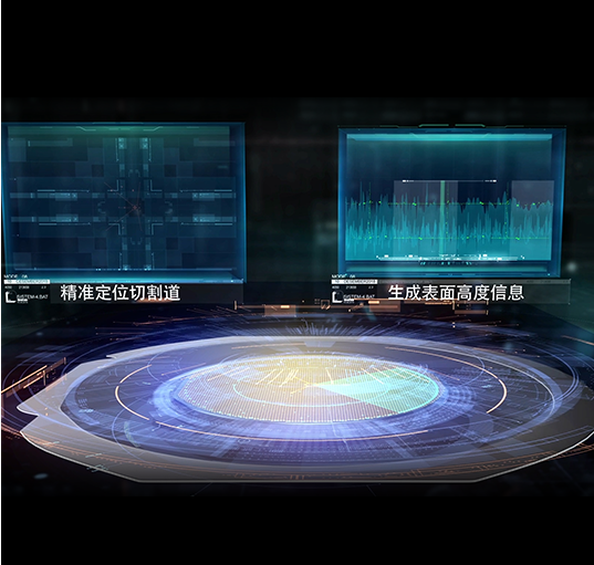

Wafer alignment programming is simple, accurate, fast and efficient.

· Initial alignment can be done on a single wafer.

· Coaxial focus confirms the machining focus.

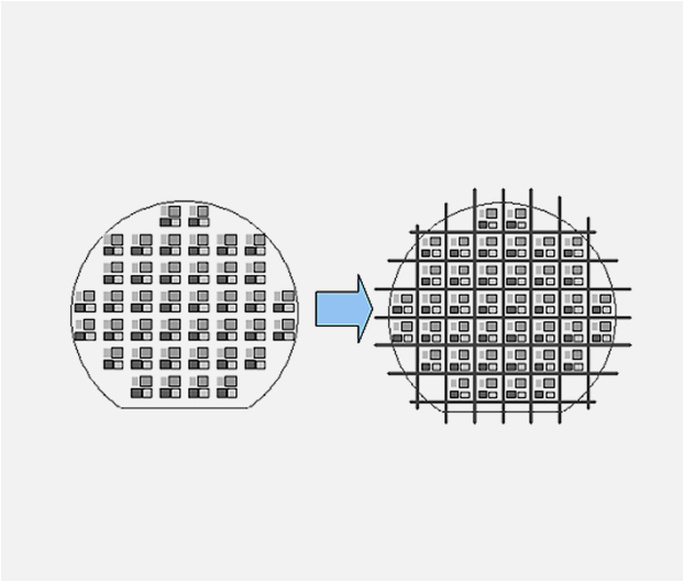

· Manually fine-tune the parallelism of the alignment cutting channel to the cutting axis.

· Precise correction of grain size

· Establish a variety of mode processing templates: low magnification, medium magnification, high magnification,

· Coaxial X-Y axis independent setting parameters to ensure cutting accuracy

· Single-chip automatic processing parameter verification mode