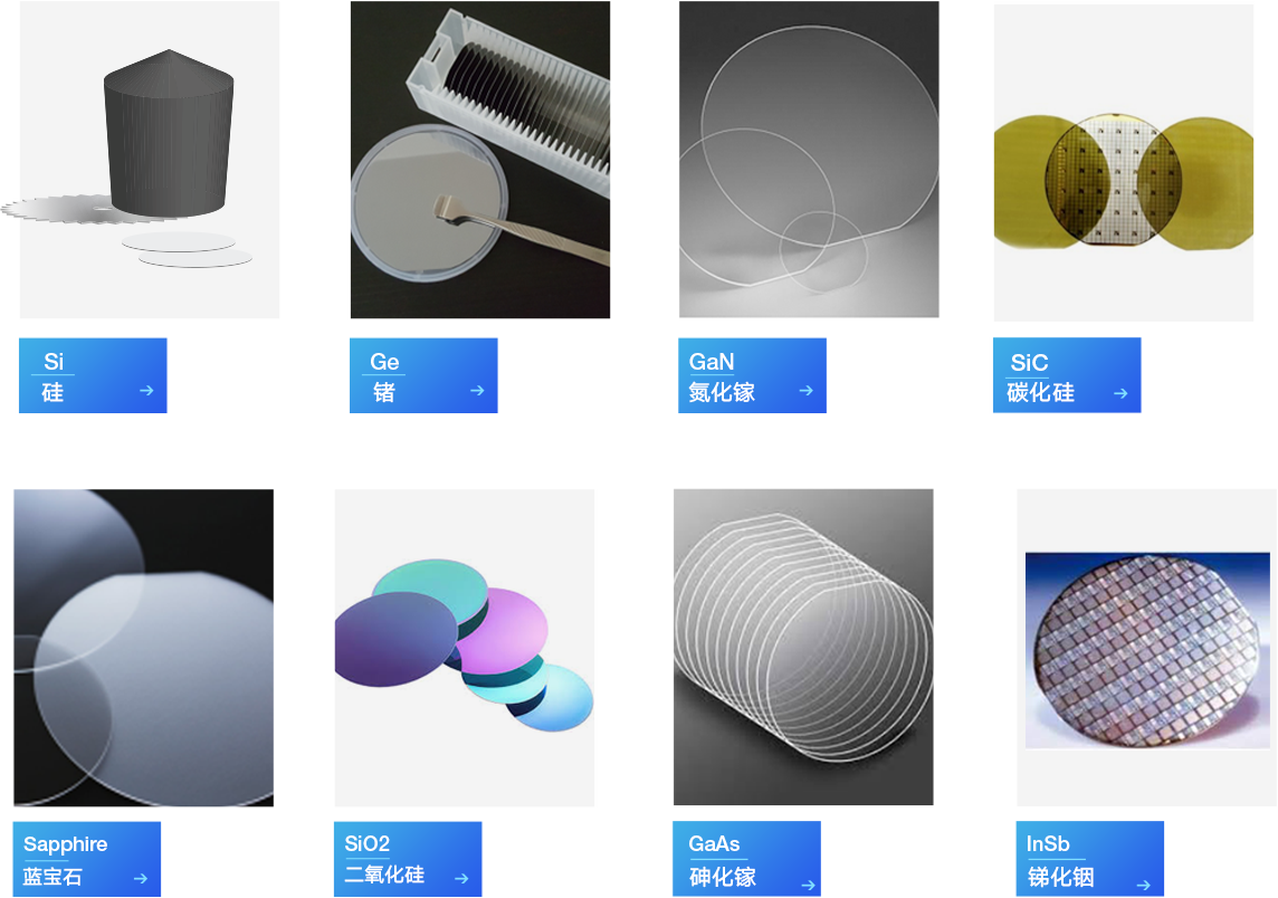

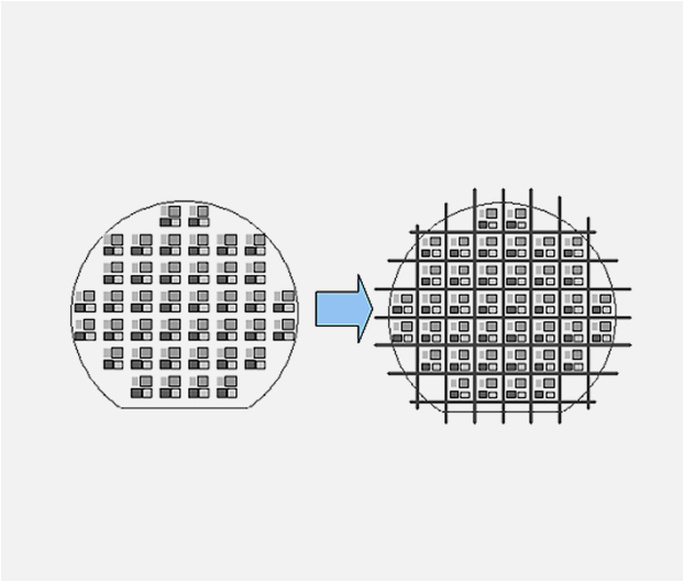

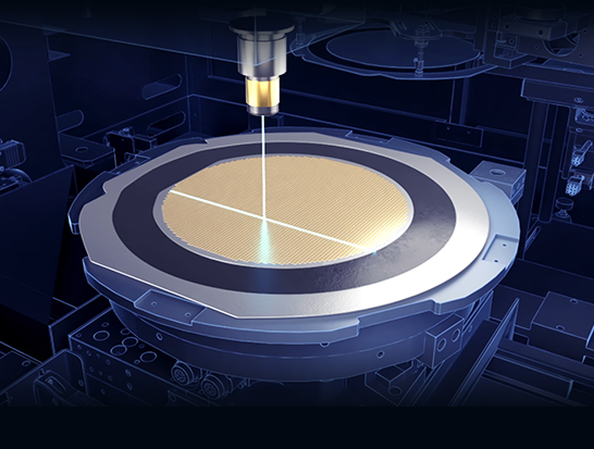

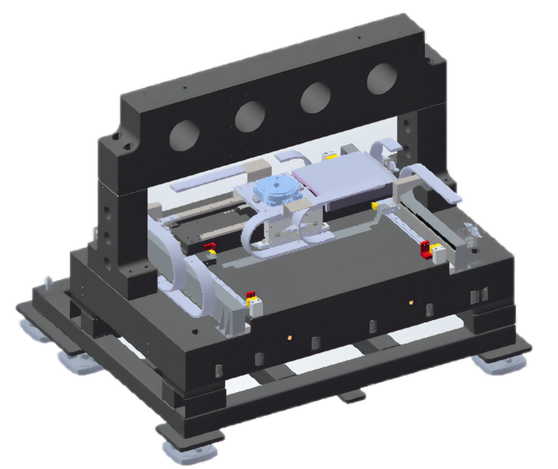

If lithography and microcircuit processing technology are the soul of wafers, the precision control, stability and efficiency in the process of "wafer segmentation" are the most important factors that determine the success of tens of millions of core circuit wafers. General HGL series invisible laser wafer cutting equipment, with accurate, efficient and stable core control technology, really provide customers with competitive wafer cutting process solutions.

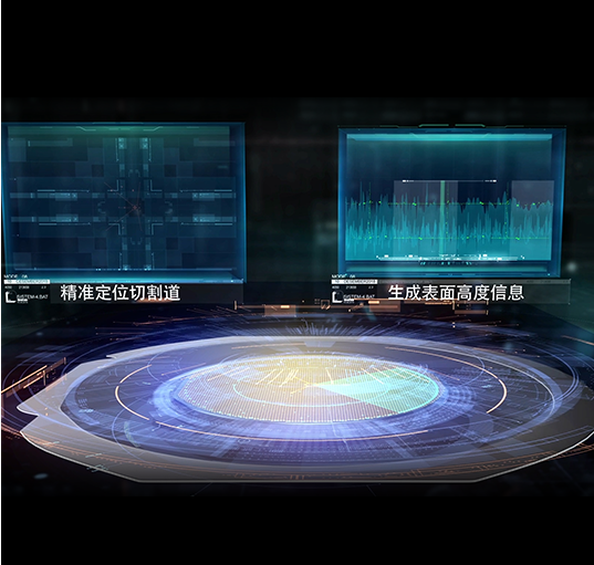

PRECISION CONTROL TECHNOLOGIES

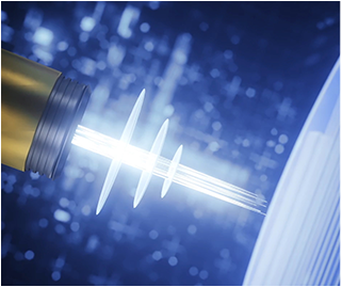

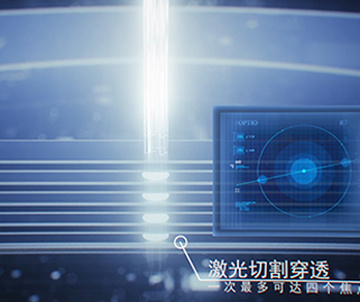

Precision focus depth control technology

For wafer laser stealth cutting equipment, the control of laser focus is one of the core technologies. The general intelligence in laser technology and laser optical path control technology has reached the advanced level in the world. However, it still needs a highly accurate and stable support platform as a guarantee in order to be effective. General Intelligence has accumulated rich manufacturing experience and precision control core technology in the application of precision automation production line for many years.