Development of Low-K Semiconductors

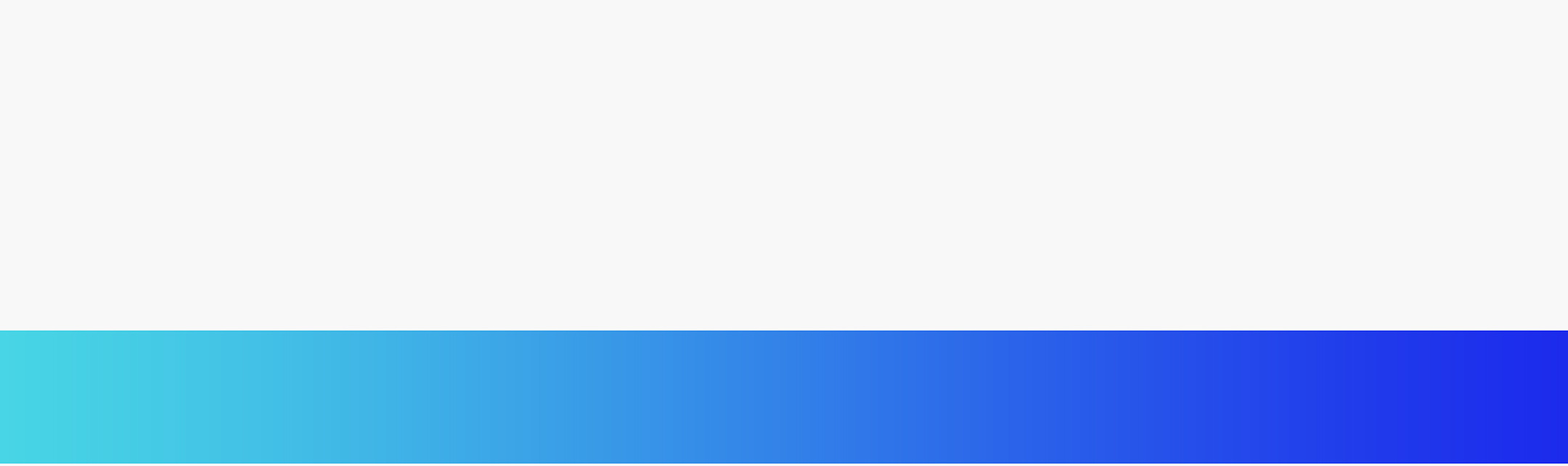

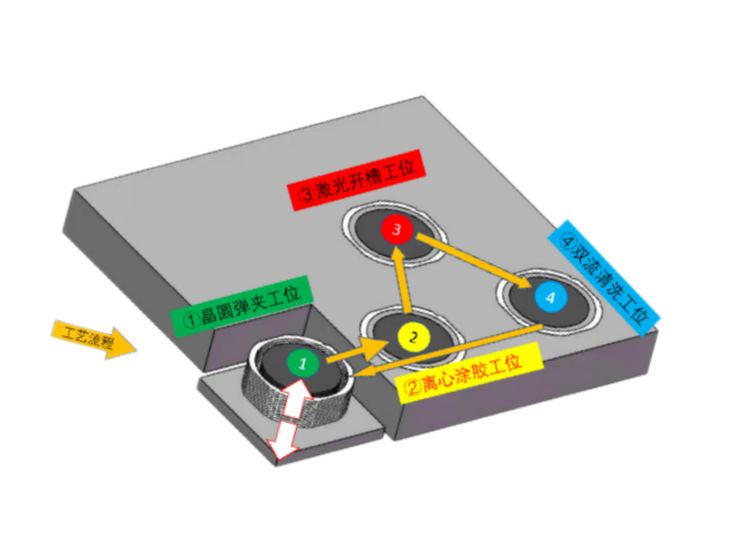

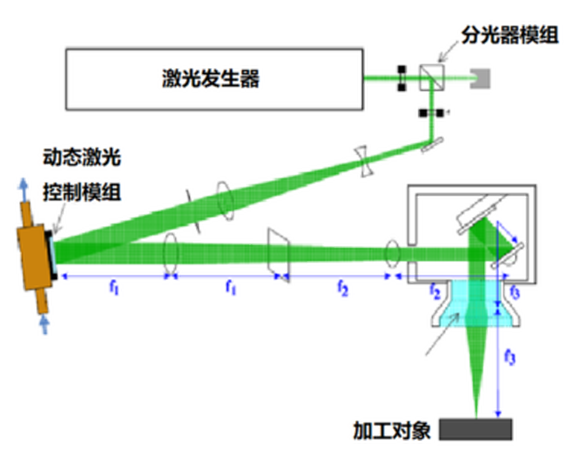

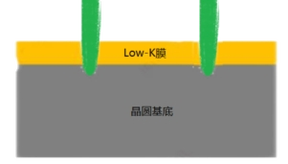

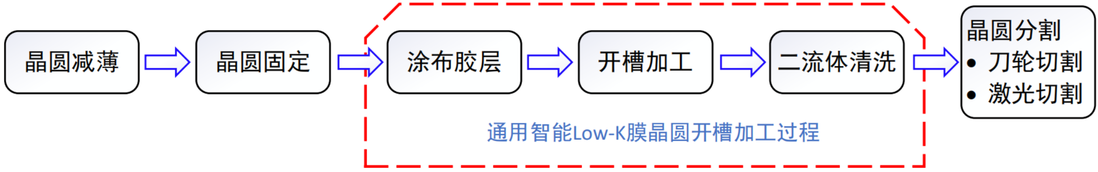

HGL1151 series is a semiconductor wafer Low-K layer slotting equipment integrated with general intelligent core technology, automatic one-stop processing, wafer feeding → pre-cleaning + protective layer coating → laser slotting → cleaning + drying → wafer blanking, all processes are done in one go. The products are equipped with high-performance laser and space light shaping system, standard ultra-high precision air-floating high-speed machining platform, real-time monitoring and real-time deviation correction in the cutting process, to ensure the accuracy consistency and quality stability of Low-K wafer slotting. This product has high slotting precision and excellent groove shape, especially the control of heat-affected zone has reached the highest international standard. The main technical performance has reached the lead in China, and some of the technical performance is better than that of similar international products, so it is the best choice to completely replace the imported slotting equipment.