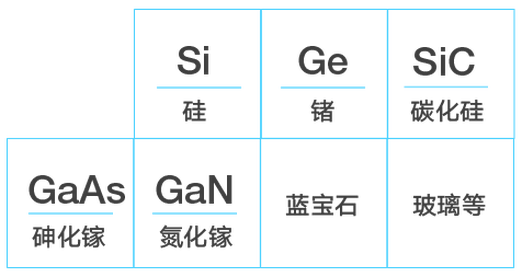

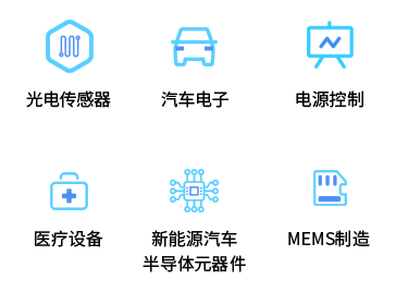

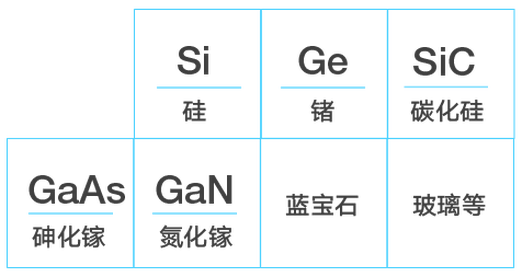

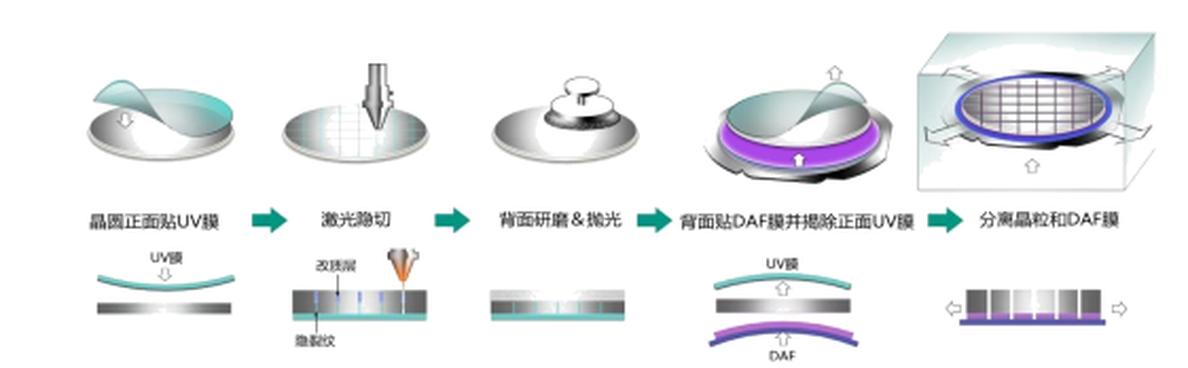

SDBG is the abbreviation of Stealth Dicing Before Grinding. The SDBG process is different from the traditional wafer cutting process. Before [wafer thinning], high-precision [internal hidden cracks] are induced by invisible laser inside the wafer, and then the wafer is thinned and polished, so that when the wafer is thinned to the thickness that needs to be retained, the stress of grinding and polishing can properly promote the directional propagation of internal hidden cracks. The independent chips on the wafer are naturally separated to obtain high-quality ultra-thin chips (such as the image above). The advantage of SDBG process is not only efficient and safe, but also can make the chip stronger (because SDBG uses the grinding and polishing stage to separate the wafer naturally, it can completely release the internal stress of the wafer caused by cutting, and there will not be quality risks such as "edge collapse" and "cracking" which cannot be avoided by traditional cutting. The ultra-thin chip obtained by SDBG process It is the most advanced, safest and most efficient ultra-thin wafer segmentation technology in the world. The advanced nature and technical advantage of SDBG technology is that it needs to be combined with system engineering such as advanced stealth laser technology, a variety of complex equipment manufacturing technology, advanced control technology and other system engineering to ensure its process effect. The key core technologies are:

1. How to accurately control the scattering of invisible laser inside the wafer substrate and form a modified layer uniformly and stably to accurately induce the development to the front of the wafer with the circuit layer and reach the positive surface of the wafer exactly. At this time, the wafer cannot split.

2. Accurately control the depth of the laser modification layer inside the substrate, so that the modification layer can not reach the range of the chip thickness that needs to be retained (20 ~ 100 μ m).

3. How to control the stress intensity and direction of internal modification to ensure the straightness and verticality quality of hidden cracks.

Based on the above technical bottleneck, SDBG process equipment has been monopolized by international equipment manufacturers for a long time, and it is a domestic technology blank equipment.